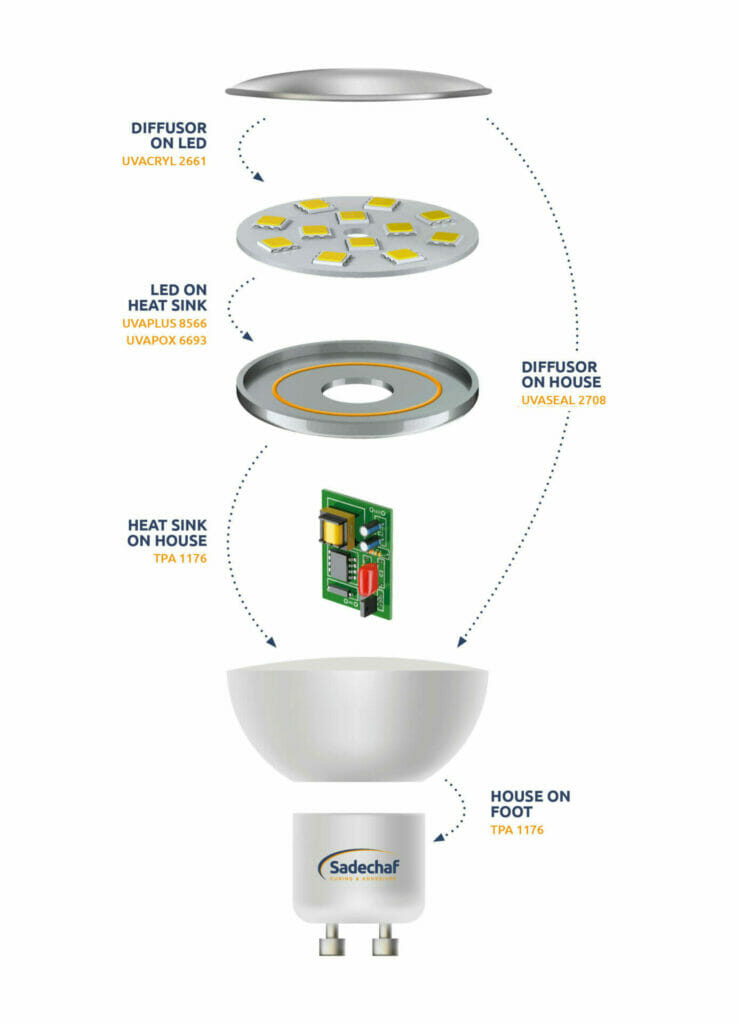

LED Assembly

Adhesives for bonding and sealing LED

New innovations continuously bring LED Lighting to higher levels in terms of performance, durability, comfort, design and new features. Sadechaf Hightech Adhesive Technology supports the development of new LED products and the optimization of production processes used in the LED industry. Our adhesives are used for LED mass production as well as niche design applications. Our adhesives and production facilities comply with the most severe quality standards for various industries such as LED manufacturing, automotive applications, aviation, space and the medical industry.

Request your free sample today, or plan a meeting with our team of adhesive experts to find a solution for your application.

Ease and comfort of use

- Fast and precise administration of the adhesive, manual or automated (a range of different viscosities and thixotropies)

- Perfectly fit for a stable and repetitive process

- Control your dosing to the max

- Project specific fine tuning of adhesives and, project specific, new developments

- UV Cure: Hyper-fast UV light curing within seconds

- Dual cure: Super-fast fixation with UV light followed by (low)-temperature curing

Extremely robust

- Extreme low shrinkage

- Extreme low outgassing

- Resistant to shocks, impacts and vibrations

- Join dissimilar materials without stress issues

- Optically clear, no yellowing or coloring, now and in the future

Perfect and permanent adhesion

- Combining high strength adhesion with a high Tg and high flexibility

- Resistant to strong forces

- Resistant to vibrations

- Stress resistant: equal distribution of forces

Your benefits

Production

- Higher efficiency

- Fast curing

- Consistent quality

- Lower cost

Product

- Higher quality and performance

- Electrical conduction = adhesion and conduction in one Aligned steadiness

- Constant strength & robustness

- New technologies, new applications

Design

- Seamless and invisible adhesion

- More design freedom

- Flexibility in shape and choice of materials

LED Adhesives Core Line up

| Adhesive | Chemistry | Component | Cure | Colour | Key properties / Application | Viscosity @23°C | Link TDS | Link Sample |

|---|---|---|---|---|---|---|---|---|

| UVASEAL 2708 | Acrylate | 1-part | UV/Visible-light & LED | Opaque | Can be used for sealing and bonding. It is a flexible adhesive to resist shocks and vibrations. Gas tight (Helium proof), Extremely low water absorption and water permeability. | 2400 mPas, Flow control | TDS UVASEAL 2708 | Sample UVASEAL 2708 |

| UVACRYL 2661 | Acrylate | 1-part | UV/Visible-light & LED | Optical clear | General purpose adhesive for plastics and glass, metals and ceramics. | 5300 mPas | TDS UVACRYL 2661 | Sample UVACRYL 2661 |

| UVAPLUS 8566 | Acrylate | 1-part | Multi-cure (UV, Heat, anaerobic and activator) | White | Thermal conductivity: 1,25 W/mK Flexible product ideal for low stress joints and bonding dissimilar substrates. Non abrasive product. Fast UV cure, heat cure from +65°C or room temperature cure. Electrical insulating. | 5380 mPas, Thixotropic gel | TDS UVAPLUS 8566 | Sample UVAPLUS 8566 |

| UVAPOX 6693 | Epoxy | 1-part | Heat cure | White | Thermal conductivity: 1,03 W/mK. High strength, High Tg product. Non abrasive product. Temperature resistant up to +200°C. Moisture and chemical resistant. Heat cure from +80°C. Electrical insulating. | 6750 mPas, Thixotropic gel | TDS UVAPOX 6693 | Sample UVAPOX 6693 |