Functioning of UV Lamps

Functioning of UV lamps

UV curing and photo-polymerization

UV Curing is based upon the principle of photo-polymerization. A liquid is irradiated with photons, produced by a UV light source. These will transfer the liquid into a solid mass. The technique of UV curing makes it possible to cure in milliseconds paints, inks, adhesives and plastics.

The advantages of UV Curing:

- Fast curing

- Increased production speed

- Reduction on time for treatment

- Only curing when irradiated

The advantages of the UV Curing product:

- High scratch resistance

- High chemical resistance

- High gloss

- Reduction of odor

- More sharp printing

Additional advantages of UV curing are the compact design of the UV dryer, the low installation cost, the use of solvent free inks and paints. UV curing technology is being applied in a variety of industries: wood, ceramics, printing, packaging, microelectronics, cans, plastics, etc.

What is UV light?

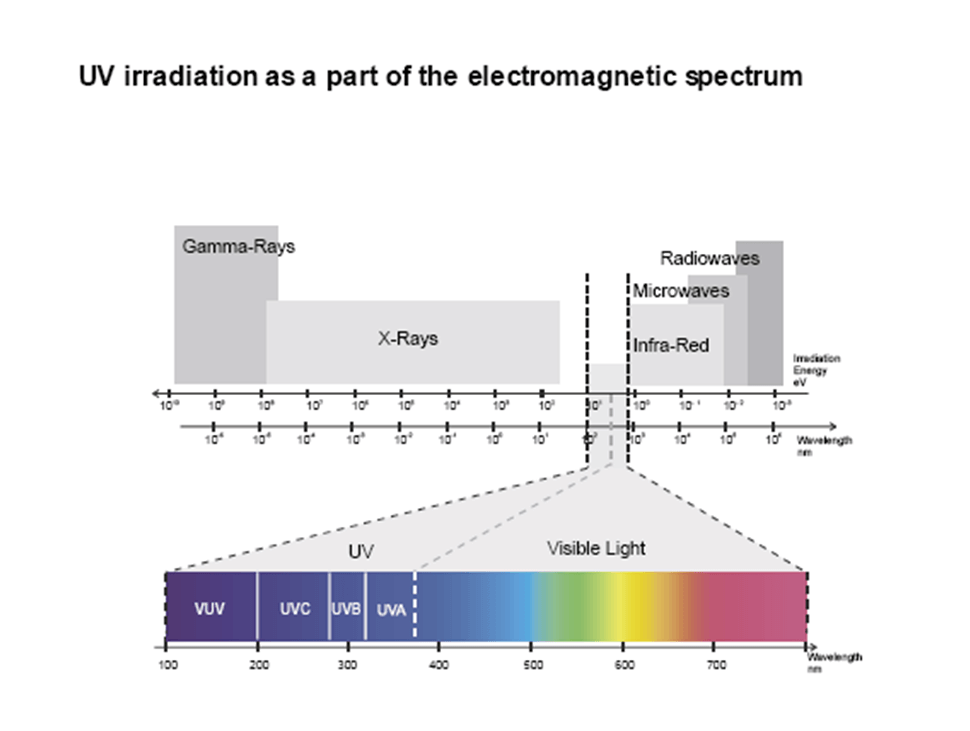

The electromagnetic spectrum

UV light is a part of the electromagnetic spectrum. it contains the radiation between 40nm (nanometer) and 400 nanometers. UV radiation is generally divided into 3 categories:

- UVA: 315-400 nm

- UVB: 280-315 nm

- UVC: 20-280 nm

production of photons

By exciting the atom with electrical current the electrons try to escape to a higher level. As each atom strives for its base model, the electrons fall back at their normal level and in this process they release each time a specific dose of energy: a photon. Thus radiation exists out of billions of such small photons.

Emission spectrum

Each atom has its own specific emission spectrum. Ink producers mix photo initiators in their product. These photo initiators capture the energy at different wavelengths and start the photopolymerization.

The UV lamp

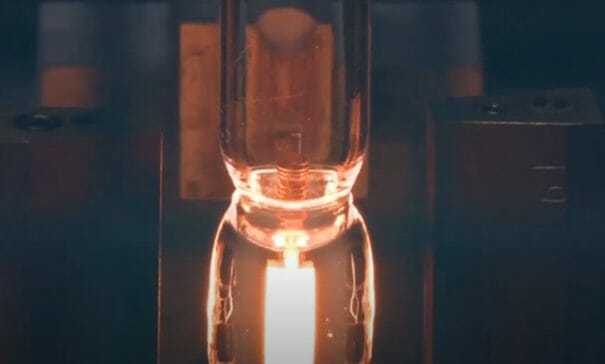

The lamps used in our curing devices are Mid Pressure Mercury Vaporation lamps. The lamps turn 29% of their power into UV radiation. UV lamps have an arc length of a few centimeters up until more than two meters and the power varies from 50 Watt per centimeter until 300 Watt per centimeter.

How is a UV lamp being produced?

A UV tube consists out of pure silica quartz (20 until 25 millimeters of diameter), having at each site an electrode. The thin ends of the lamp are being melted around a molybdenum plate. This can expand and contract together with a quartz whilst warming up and cooling down.

The electrode consists out of a small tungsten stick closest with torium, around which a tungsten wire has been wrapped. Argon and mercury are at the inside the lamp.

Starting up of a UV lamp

At the starting of phase we firstly see a modest radiation of 185 until 253.2 nanometers. a significant part of the electrical current is being transformed into heat and this rise of temperature will evaporate the mercury. This causes an increase of the pressure. The electrical resistance rises, until all the mercury is vaporized necessary voltage is reached.

Restart of a UV lamp

By turning off the UV lamp, electrons will immediately re-connect with the ions, this increases the electrical resistance. This explains why the lamp cannot be restarted until the lamp is being cooled completely and the and the mercury is completely condensed. A restart can take a few minutes, this is normally not acceptable. That is why shutters are being used, these will protect temporarily the lamp and put it in standby whenever production is being stopped and the product remains immobilized under the lamp.

Lifespan of a UV lamp

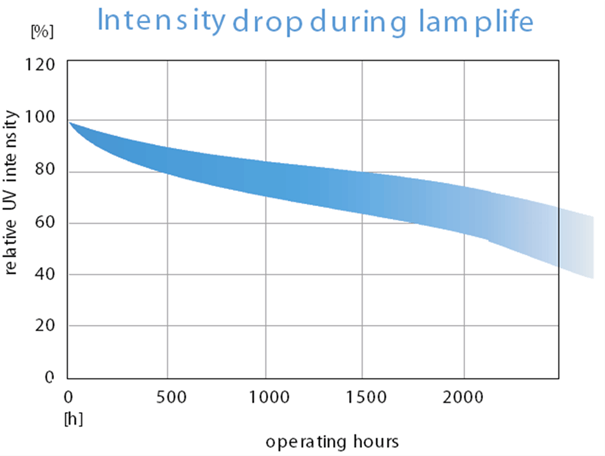

The degradation process of our UV lamps is very slow. The reduction of the UV output is being caused by the electrode material that we lauch overtime on the inside of the quartz. This will reduce the transparency of the quartz, specifically at lower UVC wavelengths.

The guaranteed lifespan of our lamps is 1000 hours. However there is no rule for changing lamps because the output of a lamp is dependent on the cooling, the reflectors, the steering, the switching, etc

Safety

There are three safety aspects related to UV lamps:

- UV radiation

- ozone production

- high voltage

UV radiation

Exposure to UV radiation causes damage to the skin and the eyes. high doses lead to sunburn. the eyes are the most sensitive to UV radiation. Welding eyes and snow blindness are the symptoms this can be very painful, but it will not leave permanent damage. A good UV installation will shields the direct radiation of the lamp and reflectors by the means of a very narrow throughput slot and shielding plates.

Ozone production

Is toxic and can damage the cells at the surface of the skin. The threshold value for ozone is 0.1 PPM any higher concentrations will cause irritation of the skin and a dry feeling in the throat. UV lamps produce ozone at the startup and to a lesser extent whilst burning. The concentration of the ozone in the ventilation channels rarely exceeds 0.3 PPM. Ozone will dissolve very fast in the air and drop to the 0.1 threshold value.

High voltage

UV lamps operate at voltages far above the mains voltage. In order to reduce the risk, all installations must meet the regulations valid.

Maintenance

A lamp can easily stay operational for over 1500 hours. The UV output will then reduce by 25%. usually lamps are being exchanged at that point in time. UV lamps contain mercury and thus must be disposed of appropriately.

Never touch the lamps with your bare hands: the grease of our skin will remain on the quartz, will then burn and form a black spot. the black spot will be nontransparent and will cause glazing of the lamp, this will cause the lamp to rupture.

It is recommended to regularly clean the reflectors and the lamps with isopropyl alcohol. The dust which is being blown by the ventilator over the lamps will burn into the quartz and causes a foggy shine over the lamp which will reduce the UV output dramatically. A regular replacement of the filters will prevent this.

The UV lamp always needs to be mounted loose and can never be fixed tightly in its brackets. This in order to cope with the expansion coefficient between the lamp and the material when expanding and shrinking. A good advice: always keep a spare lamp in stock!

During maintenance only use warm resistant Teflon coated high voltage cables. When replacing a UV lamp always check the cooling of the system: are the filters still clean? Is the arrows not damaged?

UV radiation it’s hazardous for eyes and skin! Never look straight into the lamp! Any escaping light needs to be shielded.