Automotive & E-Mobility Industry

Sadechaf has developed leading high-tech adhesive technologies for customers operating in a diverse range of the most demanding automotive, mobility and electronics manufacturing industries. Sadechaf Hightech Adhesive Technology enables the very latest evolutions in product- and production innovation. Whilst at the same time securing large scale production with higher efficiency and extreme levels of stability, quality and supply chain security.

Innovation, security, stability, ecology: those are key words which we embrace without compromise when we put an adhesive on the market.

As a result of the relentless efforts to go beyond the existing standards in the adhesive industry, and through our unique positioning in the adhesive industry, our way of working and caring as a flexible family business, Sadechaf delivers unmatched competitiveness in terms of products, production cost and environmental performance. The performance and peace of mind for our customers drive our business.

Request your free sample in the table at the bottom of this page, or contact our team of experts directly.

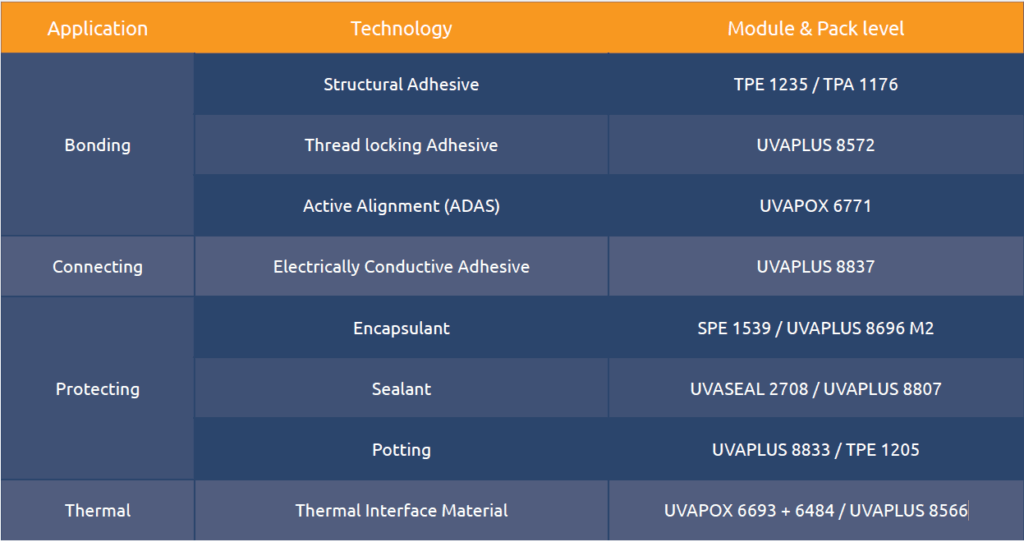

Battery Modules & Battery Packs

Important features

- Flame-retardant

- Compensate different CTE’s of materials

- Protection against vibration

- Optimal acoustic performance

- Tested & tried with (flame-retardant) plastics

Fast and reliable production process

- Easy and clean dispensing

- Cure-on-demand (UV-Light, Heat, Moisture and more)

- Fast cure (<10sec)

- Ready to use packaging

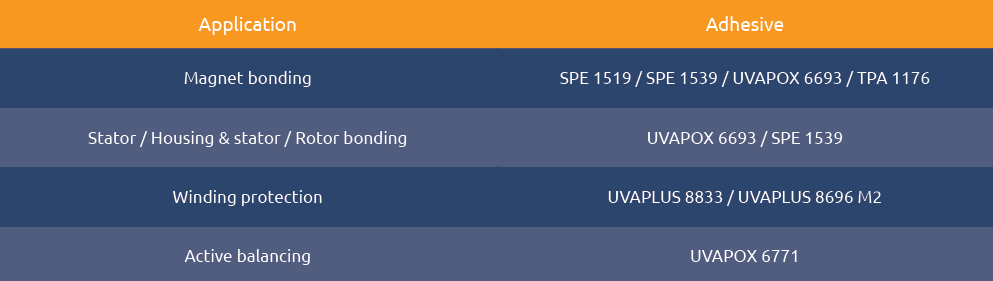

E-Motors

Important features

- Maximum structural strengths

- Exceptional temperature resistance

- Exceptional resistance against chemicals (oil, glycol, and many more)

- High Tg

- Fast curing (UV-Light, Heat, Moisture and more)

- Optimal heat transfer for thermal management

- Perfect protection against vibration

- Durable under the toughest conditions

Thermal Interface Materials

Important features

- Maximum structural strengths

- Exceptional temperature resistance

- Exceptional resistance against chemicals (oil, glycol, and many more)

- High Tg

- Fast curing (UV-Light, Heat, Moisture and more)

- Optimal heat transfer for thermal management

- Perfect protection against vibration

- Durable under the toughest conditions

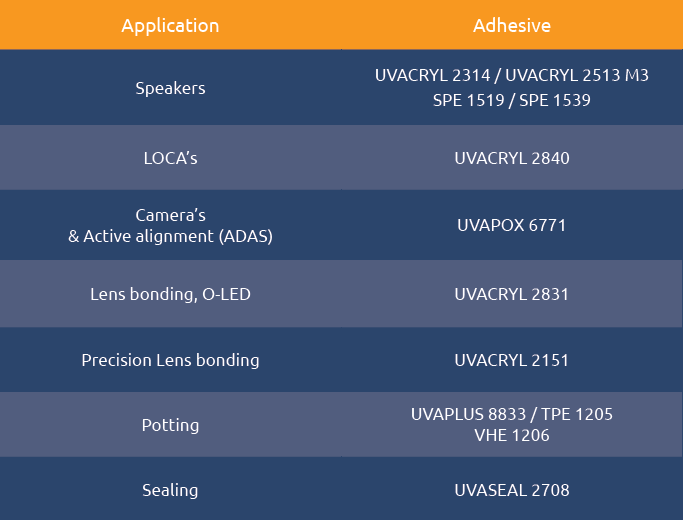

Electronics, Pottings & Sealants

Highlights for the Automotive & E-Mobility

| Adhesive | Chemistry | Component | Cure | Colour | Key properties / Application | Viscosity @23ºC | Request TDS | Request Sample |

|---|---|---|---|---|---|---|---|---|

| UVACRYL 2314 | Acrylate | 1-part | UV/Visible-light & LED | Yellow opaque | High strength adhesive, toughened, good adhesion to glass, metals and ceramics. Can be used for bonding voice coil to damper for loudspeakers | 2150 mPas | TDS UVACRYL 2314 | Sample UVACRYL 2314 |

| UVACRYL 2513 M3 | Acrylate | 1-part | UV/Visible-light & LED | Yellow opaque | Good adhesion, flow control, fast cure. Good balance of mechanical properties. Can be used for bonding loudspeakers (tweeters) | 3980 mPas | TDS UVACRYL 2513 M3 | Sample UVACRYL 2513 M3 |

| UVACRYL 2661 | Acrylate | 1-part | UV/Visible-light & LED | Optical clear | General purpose adhesive for plastics and glass, metals and ceramics. High strength, good flexibility. Moisture resistant. | 5300 mPas | TDS UVACRYL 2661 | Sample UVACRYL 2661 |

| UVASEAL 2708 | Acrylate | 1-part | UV/Visible-light & LED | Opaque | Flexible sealant with low waterabsorption, low water permeability. Gas tight (passed Helium test under vacuum). | 5300 mPas | TDS UVASEAL 2708 | Sample UVASEAL 2708 |

| UVAPLUS 8566 | Acrylate | 1-part | Multi-cure (UV, Heat, anaerobic and activator) | White | Thermal conductivity: 1,25 W/mK Flexible product ideal for low stress joints and bonding dissimilar substrates. Non abrasive product. Fast UV cure, heat cure from +65°C or room temperature cure. Electrical insulating. | 5380 mPas, thixotropic gel | TDS UVAPLUS 8566 | Sample UVAPLUS 8566 |

| UVAPLUS 8572 | Acrylate | 1-part | Multi-cure (UV, Heat, anaerobic and activator) | Opaque | High strength multi-cure product for bonding or thread locking adhesive. | 630 mPas, semi thixotropic | TDS UVAPLUS 8572 | Sample UVAPLUS 8572 |

| UVAPLUS 8696M2 | Acrylate | 1-part | UV/Heat cure | Clear | Good adhesion to common and difficult to bond plastics (COP, LCP, PPE+PS) as well as glass and metals. High strength, High Tg, Fast UV cure, low temperature heat cure. | 14000 mPas | TDS UVAPLUS 8696M2 | Sample UVAPLUS 8696M2 |

| UVAPLUS 8833 | Acrylate | 1-part | UV/Heat Cure | Clear / Yellow | Flexible potting/encapsulant/sealing product. Low E-modulus. Temperature (+150°), moisture, oil and glycol resistant. Thermal shock resistant from -40°C to +150°C. Good electrical insulating properties. | 50000 mPas | TDS UVAPLUS 8833 | Sample UVAPLUS 8833 |

| UVAPLUS 8837 | Acrylate | 1-part | Heat cure | Silver | Flexible electrically conductive adhesive. Volume resistivity 0,0001 Ohm.cm. Suitable for electrical connections or pads. Low temperature curing (100°C) | 7000 mPas | TDS UVAPLUS 8837 | Sample UVAPLUS 8837 |

| SPE 1519 | Epoxy | 1-part | Heat cure | Black | Flexible epoxy, ideal for bonding materials with different CTE. Good resistance to shocks, vibration and impact. Can be used for high temperature resistant loudspeakers up to +200°C | 36000 mPas | TDS SPE 1519 | Sample SPE 1519 |

| SPE 1539 | Epoxy | 1-part | Heat cure | Black | Strong toughened epoxy, High strength over broad temperature rance of -40°C to +150°C. Can be used for high temperature resistant loudspeakers up to +200°C | 35000 mPas | TDS SPE 1539 | Sample SPE 1539 |

| TPE 1205/VHE 1206 | Epoxy | 2-part (5:1) | 24 hours at 23°C | Clear, can be coloured | Good flow properties, potting or encapsulating of electronics, Good heat resistance, atmospheric resistance and resistant to chemical degradation. Good electrical insulating properties | 1000 mPas | TDS TPE 1205/VHE 1206 | Sample TPE 1205/VHE 1206 |

| UVAPOX 6484 | Epoxy | 1-part | Heat cure | White | Thermal conductivity: 1,00 W/mK. Flexible product ideal for low stress joints and bonding dissimilar substrates. Non abrasive product. Heat cure from +80°C. Electrical insulating. | 5200 mPas, thixotropic gel | TDS UVAPOX 6484 | Sample UVAPOX 6484 |

| UVAPOX 6693 | Epoxy | 1-part | Heat cure | White | Thermal conductivity: 1,03 W/mK. High strength, High Tg product. Non abrasive product. Temperature resistant up to +200°C. Moisture and chemical resistant. Heat cure from +80°C. Electrical insulating. | 6750 mPas, thixotropic gel | TDS UVAPOX 6693 | Sample UVAPOX 6693 |