UV LED

UV LED

UV LED curing is becoming ever more widespread due to the many benefits this technology offers. One of the main reasons the technology is on the rise is the fact that it is easy to convert a conventional UV lamp into a UV LED one. Even though the use of LED technology requires greater investment, this is more than made up for by the benefits it offers: energy savings, a longer lifespan and less heat generation.

Why UV curing?

With UV curing, your printing leaves the printing press completely dry, meaning it can be finished immediately without the risk of smudging. The result is faster and higher printing press productivity, given the fact that in bi-directional printing, the system can reverse immediately without the risk of any ink transferring. On top of that, your prints will look even more stunning due to the lack of ink contamination in the press. For paper types on which ink takes longer to dry in particular, UV curing makes a world of difference.

Longer lifespan – less energy – less heat

UV LED consumes up to 80% less than conventional UV lamps, despite offering more power. What’s more: while UV lamps have an average lifespan of 1,500 hours, this figure lies much closer to 30,000 hours for UV LED. One additional benefit of UV curing is that the LED inks used dry out less quickly in the press. That means rollers and ink ducts do not need to be cleaned during the week, saving you a significant amount of time. LED curing is also ready for use immediately; it needs no time at all to warm up or cool down. That means you can switch your LED system on and off during breaks in production to save even more energy.

UV LED curing enables you to print on nearly every type of medium. It is perfectly possible to mix paper and plastic without adjusting your press. On top of that, the LED modules transfer little or no heat to the substrate. That means even the most heat-sensitive substrates can be processed to the highest level of quality, as well as sensitive electronics and assemblies. At the same time, UV LED reduces by-products such as ozone and improves safety in the workplace by eliminating UV-B and UV-C wavelengths.

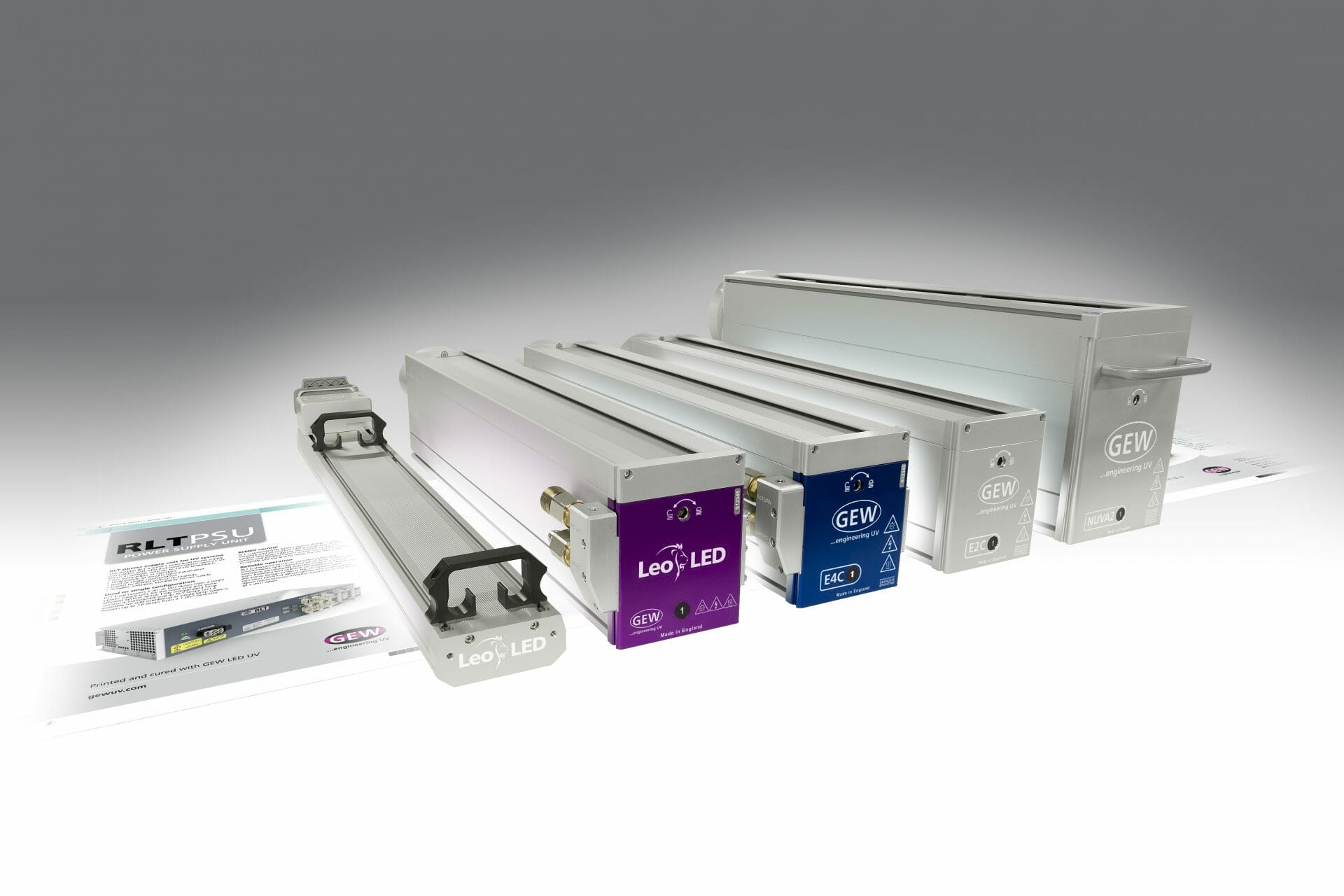

The differences between conventional UV lamps and LEDs

Aside from the requirements for UV lamps or LED systems, there are several technical differences. The main features of each technology are listed in detail below.

LED

- Variable adjustable width

- Compact design

- Water cooled or air cooled

- No powder, ozone or mercury

- LEDs can be switched on/off immediately; no energy consumption in standby

- Minimal heat transfer to the print substrate; ideal for synthetic and heat-sensitive substrates

- Long LED lifespan

- No heating or cooling cycles; immediately available

- UV-A

- No maintenance required

Conventional UV lamps

- Established technology

- Lamp offers a wide UV spectrum (UV-A, UV-B, UV-C, UV-V)

- Spectrum can easily be changed via lamp doping

- Wide range of finishing options

- Low investment cost

- Lamps and reflectors are easy to replace